Plastic Injection Molding

Versatile options for a wide range of products

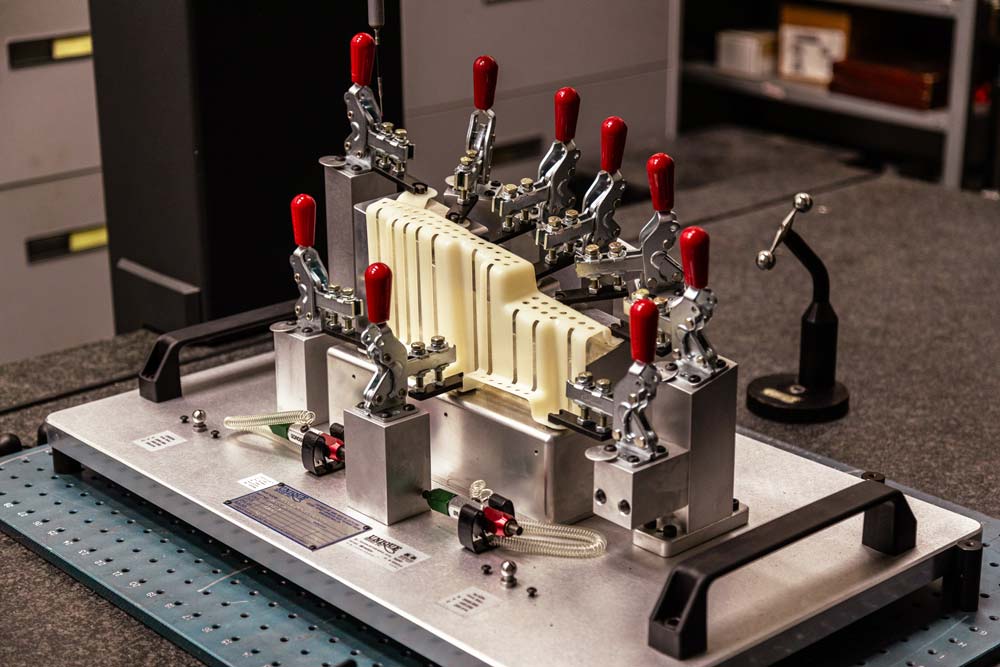

Experts in highly-efficient plastic injection molding solutions

Plastic injection molding is a highly efficient and versatile manufacturing process that enables the production of a wide range of plastic parts and components. It involves the injection of molten plastic material into a custom-designed mold to create precise and intricate parts. This process is characterized by its speed, repeatability, and cost-effectiveness.

Advantages of Plastic Injection Molding

This manufacturing process involves injecting molten plastic material directly into a mold cavity. The material then cools and solidifies, taking the shape of the mold. Finally, the mold opens, and the finished part is ejected.

- Precision Quality: High-quality plastic parts with tight tolerances.

- Reliable Repeatability: Excellent repeatability for large production runs.

- Production Speed: High-speed equipment to produce large orders in a short time frame.

Key Features and Capabilities

Our production capabilities encompass a wide range, from low to high volume production, making us your ideal manufacturing partner. With press capacities from 55 to 1,600 tons and shot sizes up to 250 ounces, we can produce everything from micro components to large, complex housings. We serve various industries with plastic injection molding, ensuring each customer’s unique needs are met with precision, efficiency, and expertise.

Low Volume Production

Perfect for prototyping, product launches, and small batch runs. We provide fast turnaround with precision tooling and high-quality results, allowing you to validate designs and enter the market quickly without committing to large tooling investments.

Medium Volume Production

Designed for consistent, repeatable output at an economical cost. Ideal for ongoing production runs or scaling up from prototypes, our medium-volume capabilities balance flexibility and efficiency while allowing for design or material adjustments as needed.

High Volume Production

Optimized for efficiency, consistency, and cost control. With multi-cavity tooling, automation, and rigorous quality checks, we deliver millions of parts annually to meet the demanding needs of OEM and Tier 1 customers with precision and reliability.

Customization

Every project is unique, and we tailor our approach accordingly. From material selection and color matching to insert and overmolding options, we adapt our process to meet your exact functional, cosmetic, and performance requirements.

Specializations

Variety of Materials

Extensive experience molding a wide range of plastics, including high-performance engineering resins tailored for applications requiring heat resistance, chemical resistance, and high mechanical strength.

Small Precision Parts

Small, intricate parts such as gears, connectors, and micro-components used in industries like medical, electronics, and precision instruments, where accuracy and detail are critical.

Overmolding

Combining different types of plastics or plastic and metal to enhance durability and functionality, ideal for components requiring a soft-touch surface or improved grip.

High-Strength Structural Parts

Expertise in producing strong, durable parts such as brackets, housings, and load-bearing components for demanding applications in automotive, industrial, and consumer products.

Let's Make GREAT Products Together

Discover how Pennant Solutions Group is redefining precision manufacturing! From simple components to complex assemblies, we specialize in delivering high-quality metal products tailored to your needs. With expertise in machining, cold heading, and custom fabrication, we partner with industries worldwide to meet the toughest demands.

Get a Quote

Ready to enhance your production with our plastics injection molding solutions? Contact us today for a personalized consultation and let’s create exceptional parts together.